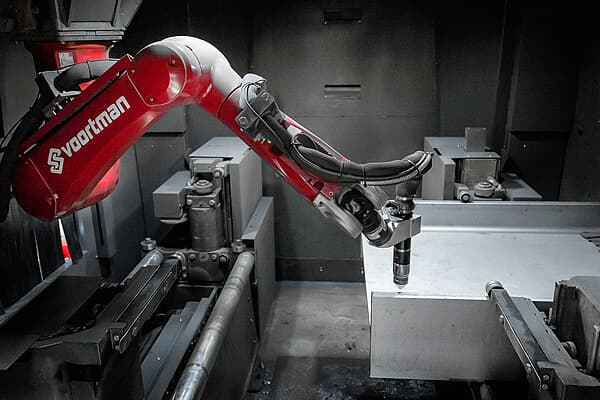

Robotic Coping Machines 8 Letters

The integrated VACAD Editor enables your operators to improve output by creating products or quickly improve and correct the product. The interface is easy to understand with straight-forward functionality. Operators will be able to take full advantage of the VACAD Editor and VACAM after a few days with the Voortman trainers.

One push of the button is all it takes to get your production done. After importing industry standard DSTV or DSTV+ (pre-nested) files into the processing list of our VACAM Software, your operator can fully focus on loading and unloading the system. No manual intervention is needed in order to keep up with the production speed of the machines.